Single Servo Walking Robot

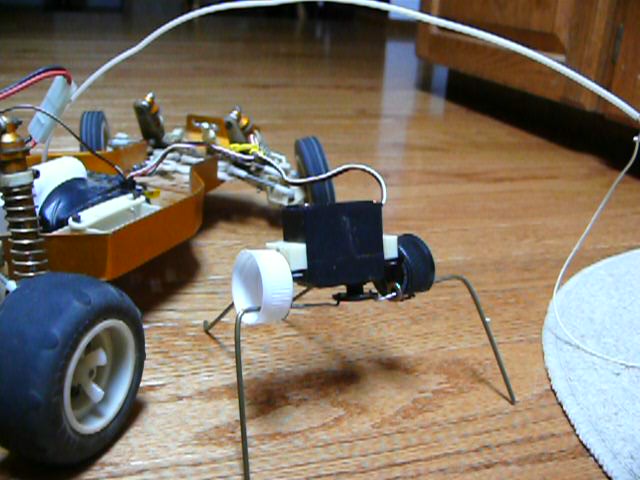

A while ago I was fortunate enough to be invited for an informal interview over coffee with the research department of one of the major auto makers. The job had to do with autonomous vehicle testing. Autonomous navigation is one of my passions, and I wanted to do everything I could to prove that I was qualified for the job. I imagined sitting in the interview, then whipping out an awesome little servo walker and having it waddle around the table. The following is a description of the walker I tried to build.

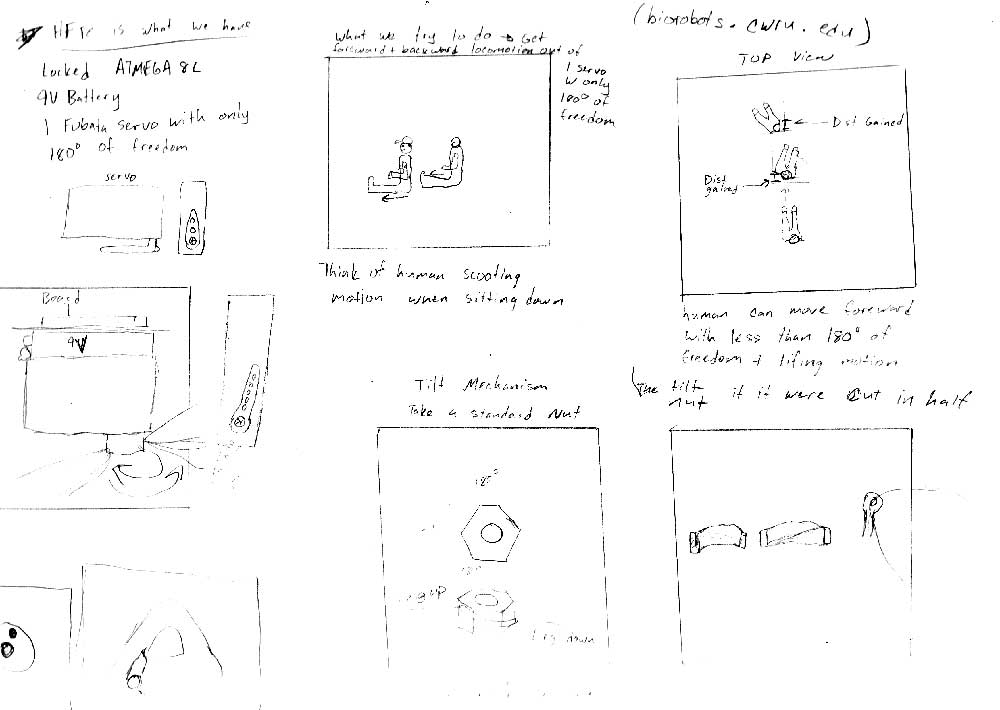

Concept Design

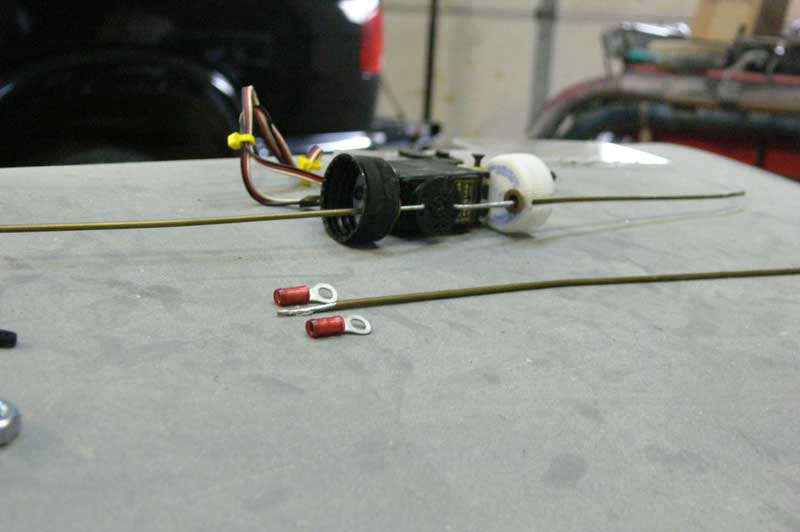

You can take a look at the "Relevant Links" on the right hand side of the page and you will see that this project has been completed successfully multiple times with a few different designs. The "Coat Hanger Walker" is probably the best functioning one-servo design I have ever come across. Of course, I am stubborn and wanted to try and build a one servo walker with supplies that could be found in any typical home.I wanted to try and make the walker out of bottle caps, coat hangers, and not much else.

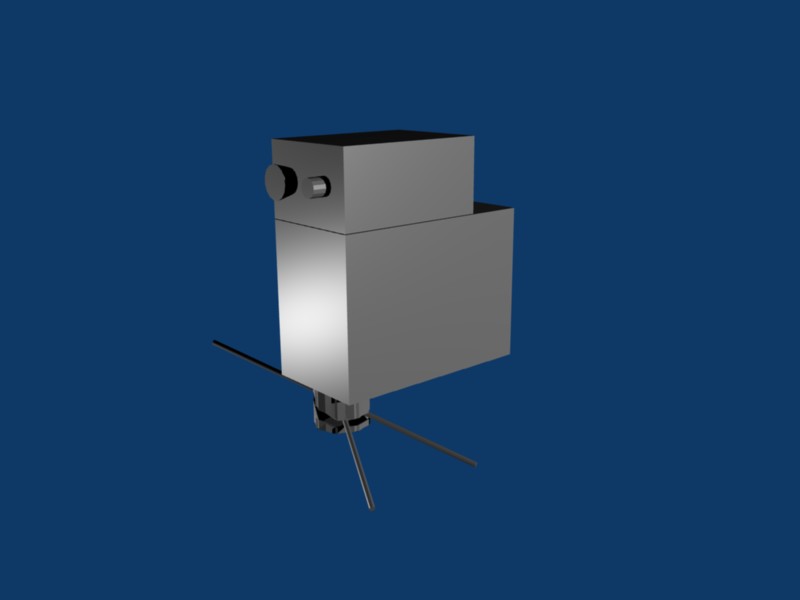

I milled over multiple designs in my head and also pondered how a human is able to scoot along on the ground while sitting on their haunches without using their hands at all. (If that sounds confusing, just take a look at the hand drawn concept and you will see a picture of a person doing what I just described). After thinking about the joint in the 3D rendering, I concluded that there was no easy way to continue with that design.