Real Time Web Sign

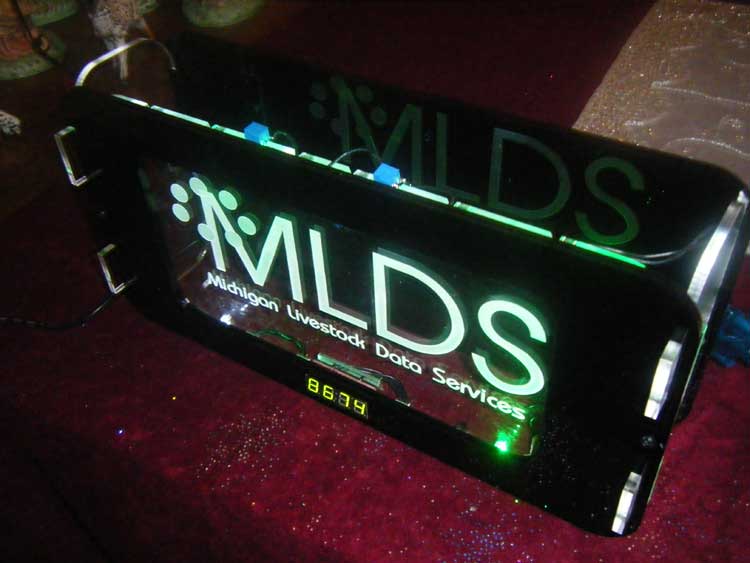

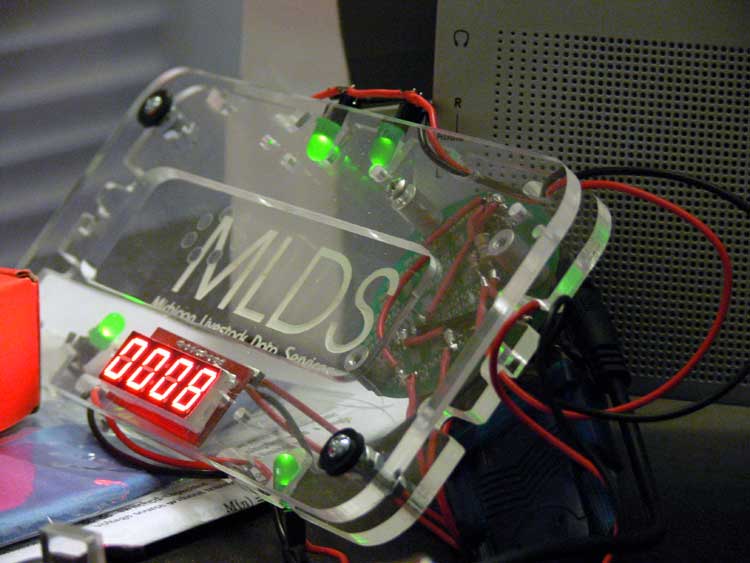

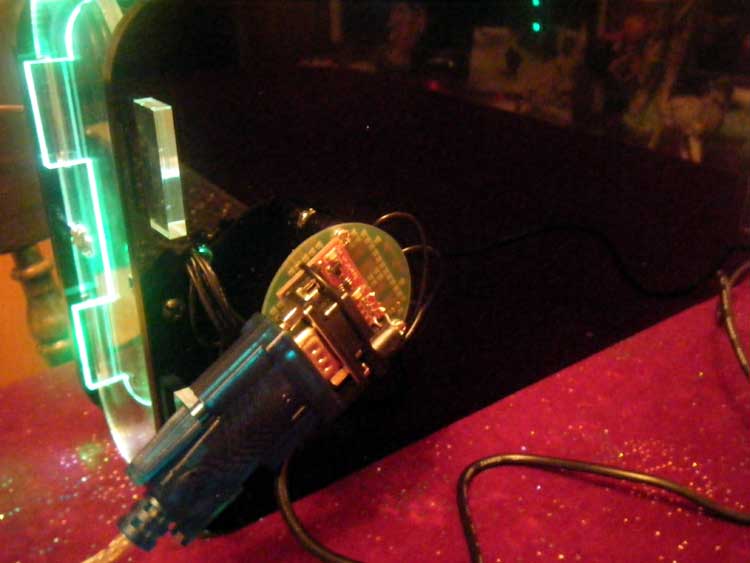

The Real Time Web Sign is a customized sign that can report web statistics for a website owner. The sign features customized laser etching on acrylic (Plexiglas), precision measurement, fit together parts, LED lighting, a 7 segment display, PC communication, and cross platform software. Development of the initial version of this project took place September 2010 to December 2010. It was created as a customized holiday present for my cousin, Brock who runs MLDS Networks and hosts several domains including this one. There are currently two signs in existence. A small prototype that was used for examining the initial materials and laser etching capability; and the large version that was assembled right on time for the holiday.

Physical Design

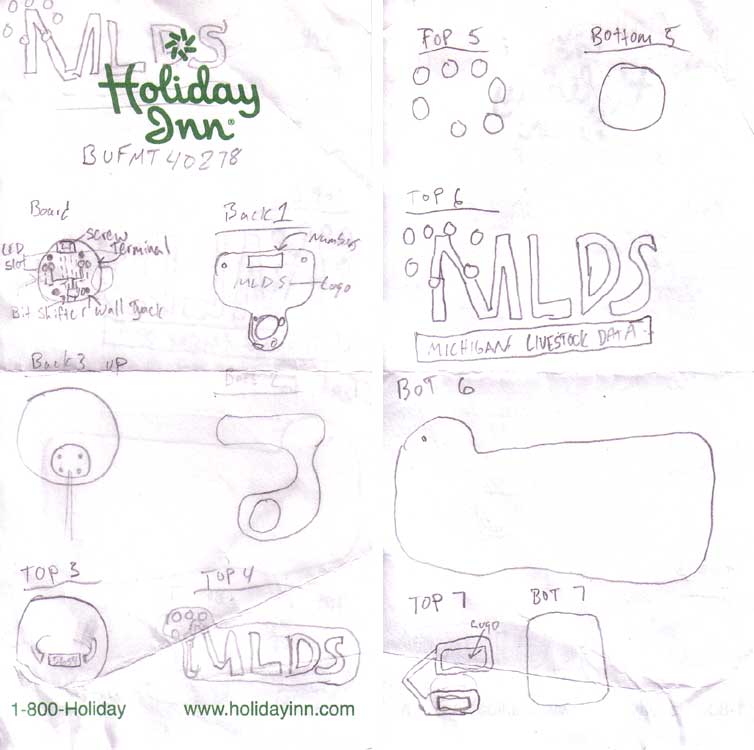

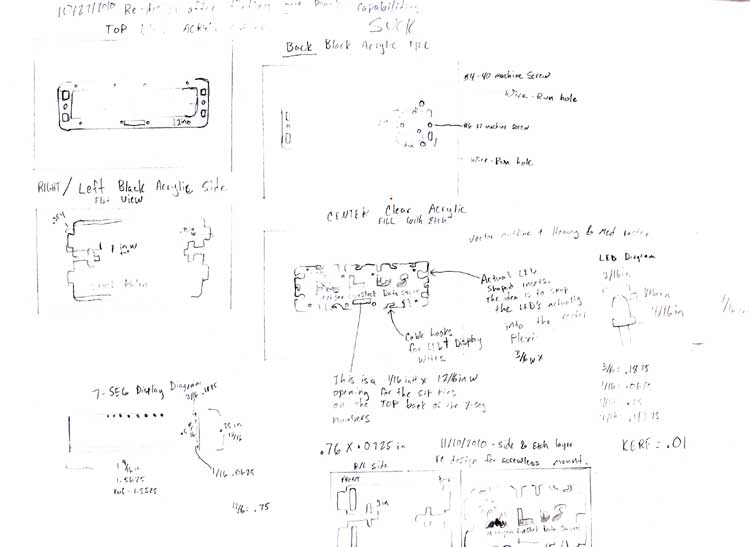

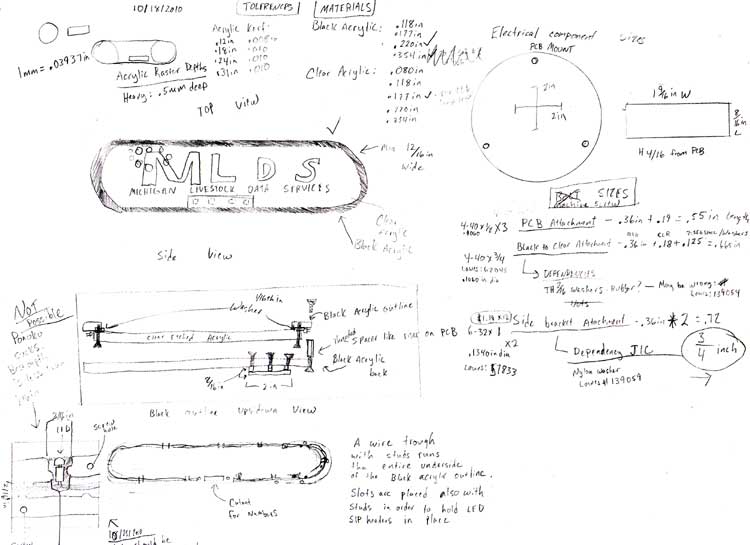

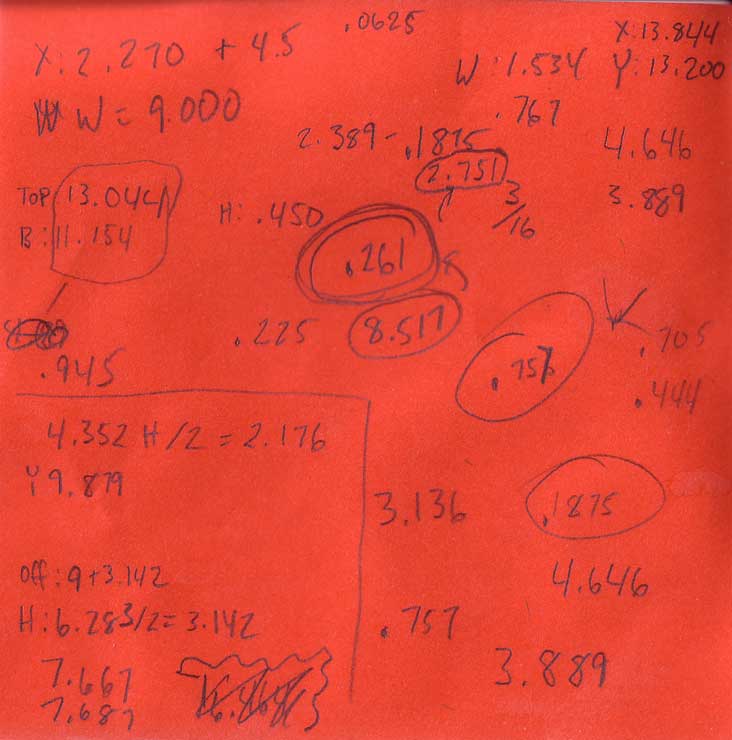

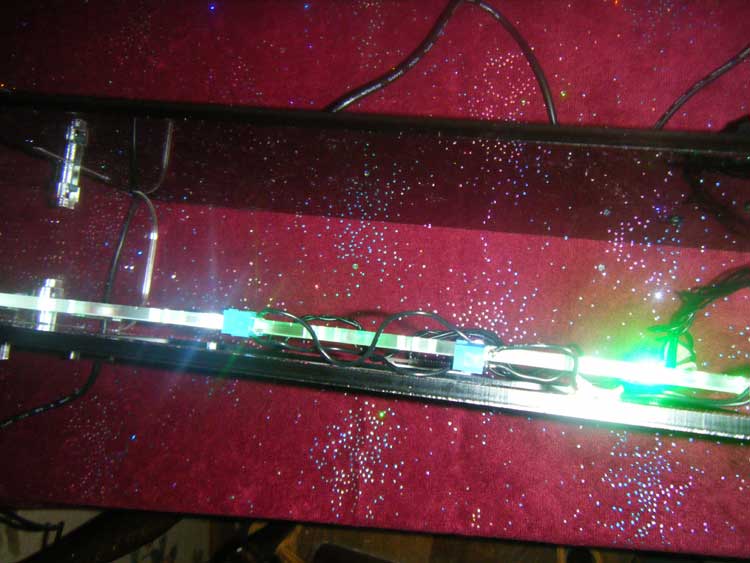

The emphasis of this project was to start to become more familiar with working on physical materials and combining those with electrical and software engineering. I'm proud of the final look of the LED's and the etched acrylic because it is very close to the vision that I had in mind from the start of the design.I started work on the physical design of this sign in September when I was in Buffalo, NY for a museum installation. I was reading about plastics manufacturing techniques at night after dinner and would get up around 5am to work on the design prior to working on the exhibits. You'll see that the image of some of the early sketches are on a Holiday Inn note pad. I specifically purchased the "Design For Manufacturability Handbook" as a guide. However, a lot of the techniques in that text book require full fledged manufacturing processes. Although it still served as a good reference for items like edges, through hole tolerances, and material bonding techniques.

Images From The Concept Design

After surveying several laser cutting services, I settled on Ponoko because I figured I could quickly adapt to their convention of using vector graphics packages, namely Inkscape and Adobe Illustrator to produce CAD designs. I learned and used Inkscape for my designs. I used Ponoko's 2D services to obtain the materials and laser cut the small prototype and large final piece. I'm not familiar with other laser cutting services, but for what I paid; I received excellent service from Ponoko. They review first time user's designs and someone will actually e-mail you if they notice any design issues.

The typical turnaround time I experienced with Ponoko for Acrylic from design submission to receiving the item in the mail was roughly five weeks.

Prototype to Version 2 Design Improvements

The prototype version had machine screws holding the faceplate, center piece, and rear piece together. It also contained several versions of wire holder notches and LED notches with slightly different sizes based on actual measurements I preformed with a protractor.In the final version I used a tab paradigm for holding all five pieces together and reduced machine screw count drastically. Measurements were adjusted for the PCB mounting holes, the seven segment display, and the T shaped joint slots were changed from #4 machine screws to #6. I also reduced the material thickness in the final design to reduce cost after examining durability in the prototype.

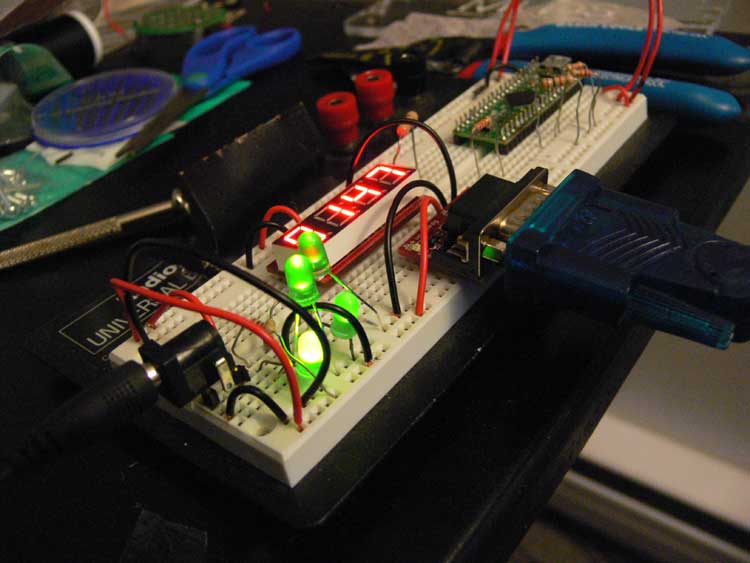

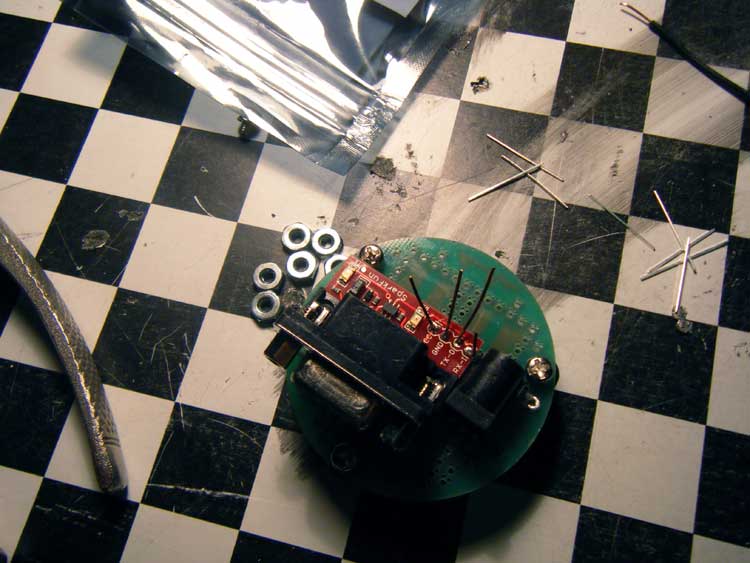

Electrical Design

The electrical design of this project was created using spare parts donated from Boston Productions Inc. It's based on a 5v power supply. Communication to the 7-segment display happens through rs232 serial using a bit shifter that converts rs232 voltage levels to ttl voltage levels. The LED's are connected using screw type terminals so that they can easily be changed. In the first version, the 7-segment display was connected using quick disconnect type headers. However, these parts fell out of my bag when I was flying home for the v2 version, so I had to improvise. The electrical design of this project has quite a few areas that could be improved on. Keep in mind that it was created using spare parts.Software Design

Software consists of both server and client applications, but the client software can be run standalone with the mod_cband Apache module.Client Software

The client software is written in Java and has been extensively tested on Windows, Mac, and Linux platforms. It can run with or without a GUI. The minimum JRE needed is 1.5. The software is wrapped in a Windows exe on that platform, and a complete mac installer and app package is provided on OSX. I also made it so that the software will detect the host OS and skin itself according to the host OS window style.The client software communicates with the sign using a comm port like COM7 or /dev/ttyUSB0, etc. It then will download a web page periodically and parse out the important information, then round the values to fit in the sign. The client application was originally created to be able to parse out any values from the Apache mod_cband module. Mod cband typically reports data traffic on a per-domain basis in killobytes. After realizing that a kilobyte display wasn't very interesting, I modified the client application to also be able to parse php scripts that read the Apache access.log and report hit counts in real time.

Server Software

Server software was developed after realizing that the mod cband output was limiting in terms of data provided. The server software allows reporting of hits to a website in real time and resides on the website that the sign is monitoring. It is a series of php scripts that can read the Apache access.log in reverse order and report file type hits, or HTTP response code hits for each day, week, or month. In order to ensure minimal server processing load, the php scripts create a cache that allows them only to process the most recent entries in the access log.Comments

The mod_cband project recently reappeared online, they may find this amusing,

http://codee.pl/cband.html

Comments are currently disabled.