Circuit Board Fabrication Tips

Sat, 03 May 2008 13:46:22 EST

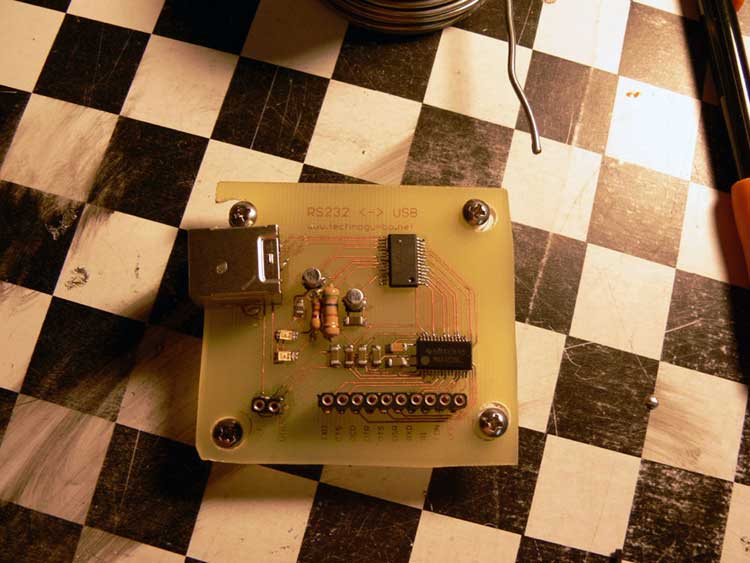

While recently putting together the PWM and RS232 boards I learned a few lessons about building circuit boards.

There are quite a few ways to make them, but I use single sided copper clad boards, Eagle to make the trace pattern, the iron on transfer method, then chemical etching using muratic acid. These may be quite trivial to those formally educated in the art, but I wanted to put up a quick list of tips just in case.

1. Place the most tricky parts on the etched circuit board first. It's a real bummer when you get 3/4 of your parts on a board and mess something up beyond repair. There goes a bunch of money that you will have to throw away. I had to do the PWM board twice because I didn't use enough flux and accidentally bridged a whole bunch of pins on one of my FTDI chips. I tried to use some smd removal compound, but accidentally tore some of the traces off of my board. I also waited to put the USB connector on last on the RS232 board. Bad idea as I had a ton of problems with one of the through hole pins due to bad drilling and almost had to scrap that board too.

2. Avoid through hole parts. As long as you have good flux and a magnifying glass, its best to just use surface mount parts. It takes a TON of time to drill all of the holes needed for through hole parts. Drilling takes extra time and also adds another step that could mess up your end product. Its pretty easy to drill traces off of a board if your bit isn't small enough. It also takes extra time to cut all of the leads. Through hole parts are also more difficult to secure on a single sided board because they can only be secured on one side of the board.

3. Use good flux. I have a water soluble flux pen that I bought after having so much trouble using my junky soldering iron with SSOP 28 pin chips. My tip is so large that it would continually cause bridges between pins. I also had trouble getting the chips securely on the board. With good flux, you will notice that the solder just sucks up onto the metal. It also helps prevent bridges, as the flux makes the solder adhere to the metal around it.

4. Scrutinize your trace pattern before etching it. The PWM board was perfect when I got it put together. However, when I tested it; I could not transmit anything to the ATMEGA chip. Careful examination of my routing pattern from Eagle showed that for some reason there was no trace ever routed between two of my pins! It turns out that it just looked like I had attached the pins in my diagram. The reality is that the trace never actually was connected in the eagle diagram and therefore was never routed! How stupid.

In other unrelated news, I am extremely happy that Adobe has lifted the restrictions on the FLV and SWF format. They have also published unlicensed specs. I'm pretty sure that this means that there may be more wide spread availability of h.264 encoding in some of my favorite open source apps..(ffmpeg and Red5). According to the Red5 mailing list though, the official specs for RTMP are what is really needed. However, I highly doubt Adobe would release this any time soon as it may lead to cannibalization of the Flash Media Server(FMS). I am glad about this though, as I hope to never have to use Microsoft's Silverlight or whatever Sun is cooking up for Java. Microsoft has already proved that they have no place for web developers. It's a nightmare to get work done using ASP in .NET as the documentation and examples suck compared to perl and php.

1. Place the most tricky parts on the etched circuit board first. It's a real bummer when you get 3/4 of your parts on a board and mess something up beyond repair. There goes a bunch of money that you will have to throw away. I had to do the PWM board twice because I didn't use enough flux and accidentally bridged a whole bunch of pins on one of my FTDI chips. I tried to use some smd removal compound, but accidentally tore some of the traces off of my board. I also waited to put the USB connector on last on the RS232 board. Bad idea as I had a ton of problems with one of the through hole pins due to bad drilling and almost had to scrap that board too.

2. Avoid through hole parts. As long as you have good flux and a magnifying glass, its best to just use surface mount parts. It takes a TON of time to drill all of the holes needed for through hole parts. Drilling takes extra time and also adds another step that could mess up your end product. Its pretty easy to drill traces off of a board if your bit isn't small enough. It also takes extra time to cut all of the leads. Through hole parts are also more difficult to secure on a single sided board because they can only be secured on one side of the board.

3. Use good flux. I have a water soluble flux pen that I bought after having so much trouble using my junky soldering iron with SSOP 28 pin chips. My tip is so large that it would continually cause bridges between pins. I also had trouble getting the chips securely on the board. With good flux, you will notice that the solder just sucks up onto the metal. It also helps prevent bridges, as the flux makes the solder adhere to the metal around it.

4. Scrutinize your trace pattern before etching it. The PWM board was perfect when I got it put together. However, when I tested it; I could not transmit anything to the ATMEGA chip. Careful examination of my routing pattern from Eagle showed that for some reason there was no trace ever routed between two of my pins! It turns out that it just looked like I had attached the pins in my diagram. The reality is that the trace never actually was connected in the eagle diagram and therefore was never routed! How stupid.

In other unrelated news, I am extremely happy that Adobe has lifted the restrictions on the FLV and SWF format. They have also published unlicensed specs. I'm pretty sure that this means that there may be more wide spread availability of h.264 encoding in some of my favorite open source apps..(ffmpeg and Red5). According to the Red5 mailing list though, the official specs for RTMP are what is really needed. However, I highly doubt Adobe would release this any time soon as it may lead to cannibalization of the Flash Media Server(FMS). I am glad about this though, as I hope to never have to use Microsoft's Silverlight or whatever Sun is cooking up for Java. Microsoft has already proved that they have no place for web developers. It's a nightmare to get work done using ASP in .NET as the documentation and examples suck compared to perl and php.

Charles Palen has been involved in the technology sector for several years. His formal education focused on Enterprise Database Administration. He currently works as the principal software architect and manager at Transcending Digital where he can be hired for your next contract project. Charles is a full stack developer who has been on the front lines of small business and enterprise for over 10 years. Charles current expertise covers the areas of .NET, Java, PHP, Node.js, Javascript, HTML, and CSS. Charles created Technogumbo in 2008 as a way to share lessons learned while making original products.

Comments

No one has posted any comments yet, be the first

Comments are currently disabled.